Why Is Matcha So Expensive?

In summary:

Shading tea plants is manual and labour‑intensive.

Harvesting combines skilled handwork with machines.

Leaves are carefully de‑stemmed and de‑veined before grinding.

Traditional stone mills produce only 30–40 g per hour, keeping supply low.

Grinders, labour, packaging, and import from Kyoto all add cost.

Global demand is high, supply is limited, and quality matcha takes time.

With matcha, you truly get what you pay for — authenticity and flavour.

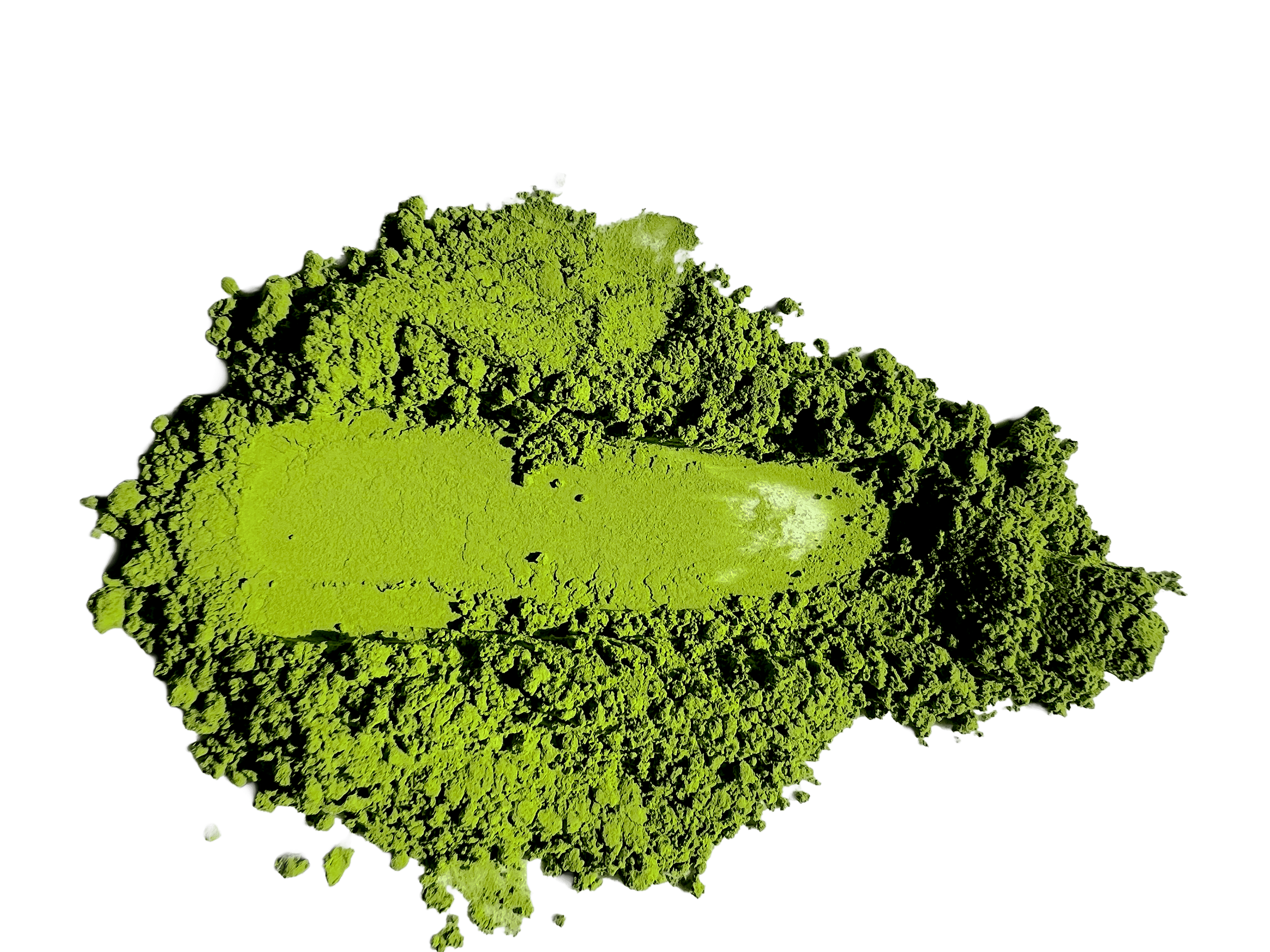

Matcha — the vibrant, powdered green tea from Japan — has become a worldwide favourite. But many people are surprised when they see the price tag. What is matcha and why is it so expensive? The answer lies in the incredible amount of manual labour and craftsmanship behind every tin. Let’s walk through what makes authentic matcha truly worth its cost.

From Shading to Harvest: A Labour of Care

The process begins weeks before harvest when farmers shade the tea fields to increase the leaves’ chlorophyll and amino acid content. This isn’t an automated task — workers manually set up large shading tents, adjusting and maintaining them throughout the growing period. It’s delicate work that directly affects the tea’s colour, sweetness, and quality.

When it’s time to harvest, the process is a blend of tradition and technology. The finest top leaves are handpicked while machines assist with precision and consistency. Even then, each leaf that ends up in ceremonial-grade matcha goes through another round of human inspection.

The Tedious Transformation: From Leaf to Powder

After harvesting, the leaves are steamed, dried, and processed into tencha, a pre-matcha material. Then comes one of the most meticulous steps — removing stems and veins so that only pure, tender leaf flakes remain. This de-veining and de-stemming step requires both care and time, ensuring the final tea has an ultra-smooth texture.

Next is perhaps the most iconic step: stone grinding. Traditional granite mills rotate slowly to protect the tea from heat, but that patience comes at a cost. Each mill produces only about 30 to 40 grams of matcha per hour — roughly eight portions per day. Stone grinders are expensive, and to meet demand, you need many of them working simultaneously. That slow, traditional method is part of what defines ceremonial matcha.

Beyond the Tea Farm: Packaging, Imports, and Market Realities

The work doesn’t stop with grinding. We import our matcha directly from Kyoto, Japan, and every tin undergoes careful packaging and labelling — part by hand, part by machine — to preserve freshness. Add transportation, customs, and quality checks, and you can see how these steps all add layers of cost.

Then there’s the market factor: matcha is experiencing a global boom. Demand often outstrips supply, pushing prices upward. Unfortunately, some brands overcharge despite offering average quality, making it harder for consumers to find truly good matcha at a fair price.

Why Paying More Can Actually Mean Better Value

With matcha, you really do get what you pay for. Cheap matcha often skips essential steps like shading or slow grinding, resulting in dull colour and bitter taste. On the other hand, authentic ceremonial-grade matcha offers a vibrant hue, rich umami flavour, and fine texture — the hallmark of patient, traditional craftsmanship.

We’re proud to offer matcha that lives up to its ceremonial name — not for hype, but for quality. Our pricing reflects fairness and honesty, even in a market where trends can distort value. When you see how much effort, precision, and passion go into each tin, the price of true matcha starts to make perfect sense.